Isothermal forging is a high-temperature forging process, which can improve the microstructure and properties of forgings, and improve the mechanical properties and heat resistance of forgings. So, what kind of forgings need to be isothermal forged?

First of all, isothermal forging is suitable for the forging of difficult-to-machine materials such as high-temperature alloys, titanium alloys, and nickel-based alloys. These materials have high melting points and are difficult to process, and traditional forging processes are difficult to meet their forming requirements. Whereas, isothermal forging can improve the plasticity and fluidity of the material by controlling the temperature and time, so as to achieve the forging of complex shapes.

Secondly, isothermal forging is suitable for forgings that require high precision. Since isothermal forging can control the deformation and deformation rate of the material, high-precision forming can be realized. This is of great significance for some parts that require high precision, such as aero engine blades, automobile crankshafts, etc.

In addition, isothermal forging is also suitable for forgings that need to improve the properties of the material. Isothermal forging can improve the microstructure and properties of materials by controlling the temperature and time during heating, holding, and cooling.

In short, isothermal forging is a very important high-temperature forging process, which is suitable for the forging of difficult-to-machine materials such as high-temperature alloys, titanium alloys, nickel-based alloys, forgings that require high precision, and forgings that need to improve material properties. In actual production, the appropriate forging process should be selected according to the specific situation to meet the product quality and efficiency requirements.

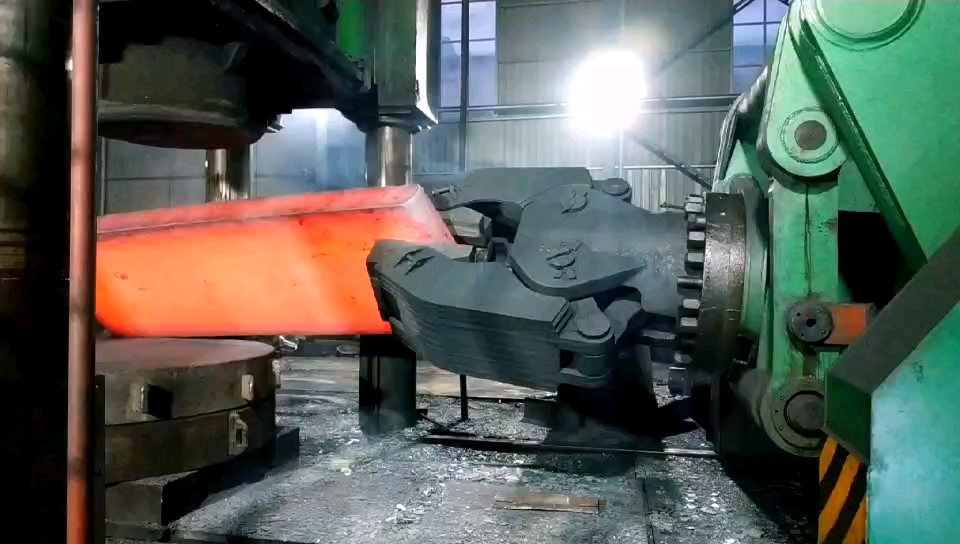

Zhengxi forging hydraulic press

The Zhengxi forging hydraulic press is a versatile forging equipment that can be used in various types of forging processes, including isothermal forging. The equipment adopts a hydraulic drive system, which can provide high-pressure, high-speed and high-precision forging force to ensure that the forged steel achieves the best physical properties and shape accuracy during the forging process. At the same time, Zhengxi forging hydraulic press also has an intelligent control system, which can realize automatic operation and data acquisition, and improve production efficiency and quality stability.