1. The PCM molding hydraulic press is mainly suitable for the molding of carbon fiber prepreg.

2. The machine is widely used in automobiles (bumpers, bottom guards, battery cases), aerospace, electric power, energy, and other industries.

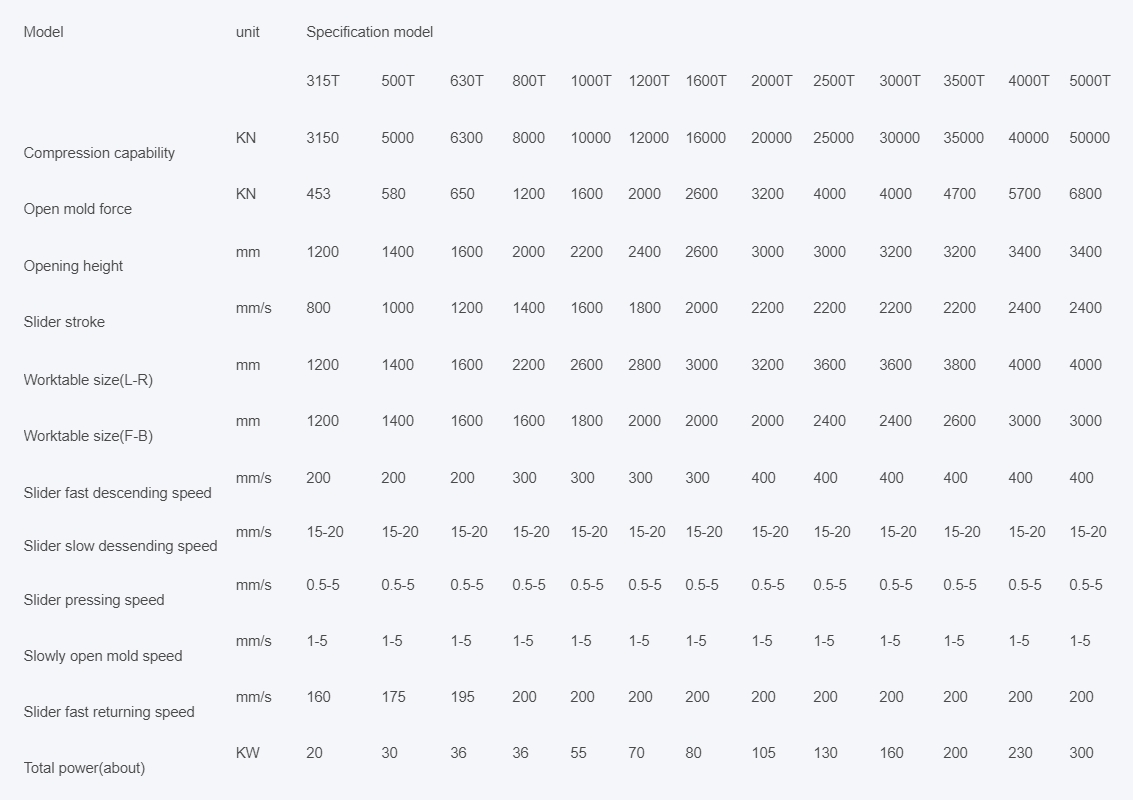

Model unit Specification model 315T 500T 630T 800T 1000T 1200T 1600T 2000T 2500T 3000T 3500T 4000T 5000T Compression capability KN 3150 5000 6300 8000 10000 12000 16000 20000 25000 30000 35000 40000 50000 Open mold force KN 453 580 650 1200 1600 2000 2600 3200 4000 4000 4700 5700 6800 Opening height mm 1200 1400 1600 2000 2200 2400 2600 3000 3000 3200 3200 3400 3400 Slider stroke mm/s 800 1000 1200 1400 1600 1800 2000 2200 2200 2200 2200 2400 2400 Worktable size(L-R) mm 1200 1400 1600 2200 2600 2800 3000 3200 3600 3600 3800 4000 4000 Worktable size(F-B) mm 1200 1400 1600 1600 1800 2000 2000 2000 2400 2400 2600 3000 3000 Slider fast descending speed mm/s 200 200 200 300 300 300 300 400 400 400 400 400 400 Slider slow dessending speed mm/s 15-20 15-20 15-20 15-20 15-20 15-20 15-20 15-20 15-20 15-20 15-20 15-20 15-20 Slider pressing speed mm/s 0.5-5 0.5-5 0.5-5 0.5-5 0.5-5 0.5-5 0.5-5 0.5-5 0.5-5 0.5-5 0.5-5 0.5-5 0.5-5 Slowly open mold speed mm/s 1-5 1-5 1-5 1-5 1-5 1-5 1-5 1-5 1-5 1-5 1-5 1-5 1-5 Slider fast returning speed mm/s 160 175 195 200 200 200 200 200 200 200 200 200 200 Total power(about) KW 20 30 36 36 55 70 80 105 130 160 200 230 300

The finite element optimization design of the main engine structure and the four-column structure have good rigidity and high precision.

Use the liquid as the medium to transmit energy, using an imported low-noise plunger oil pump.

Cartridge valve integrated system, reliable action, high cleanliness, low leakage.

Through the selection of the operation panel, two molding processes of fixed stroke and fixed pressure can be realized.

The working pressure and stroke can be adjusted within the specified range according to process needs.