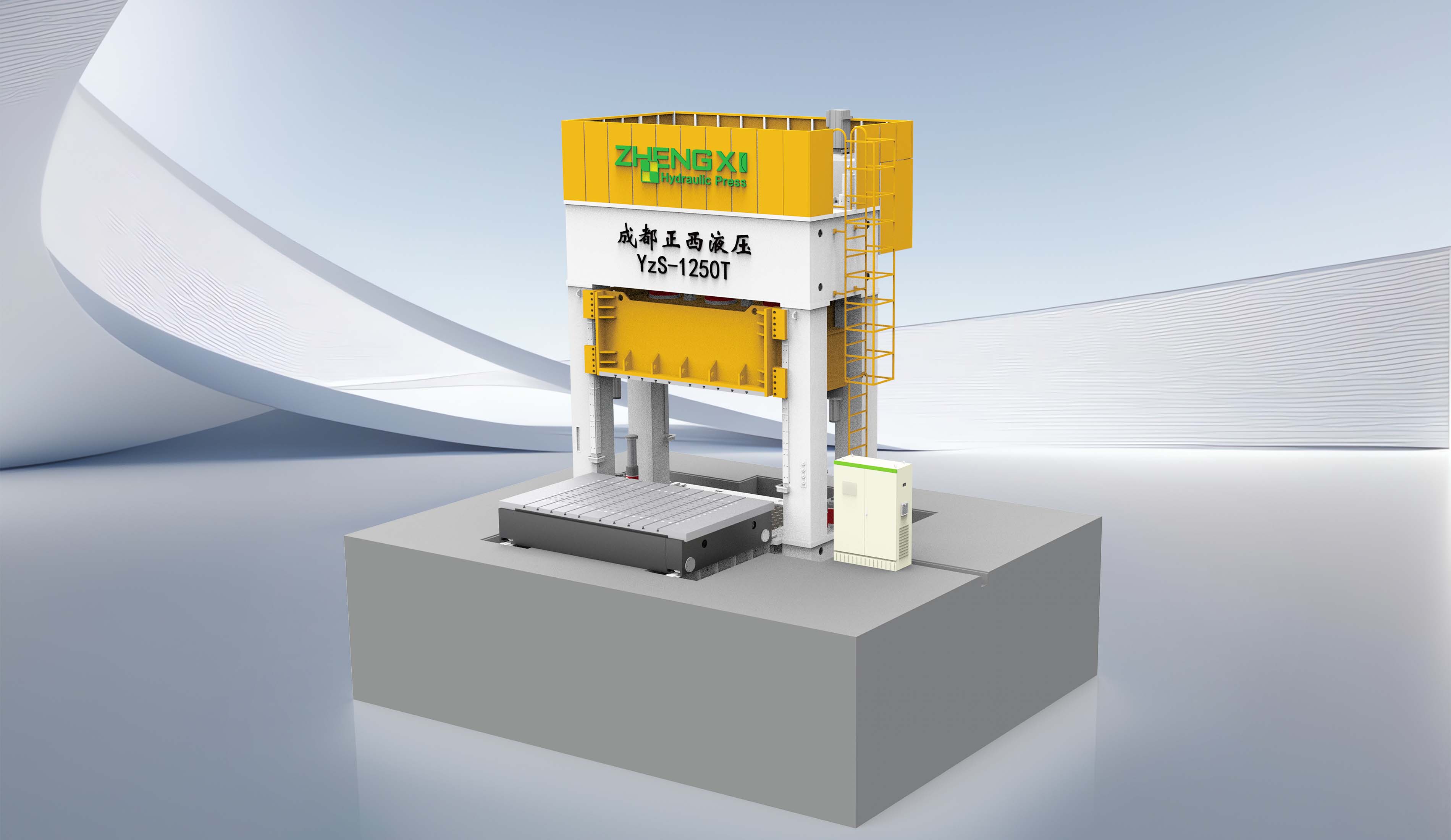

It is mainly used for the cold stamping of interior and exterior sheet metal parts of automobiles, such as the stamping of four-door and two-door covers, side panels, and chassis parts.

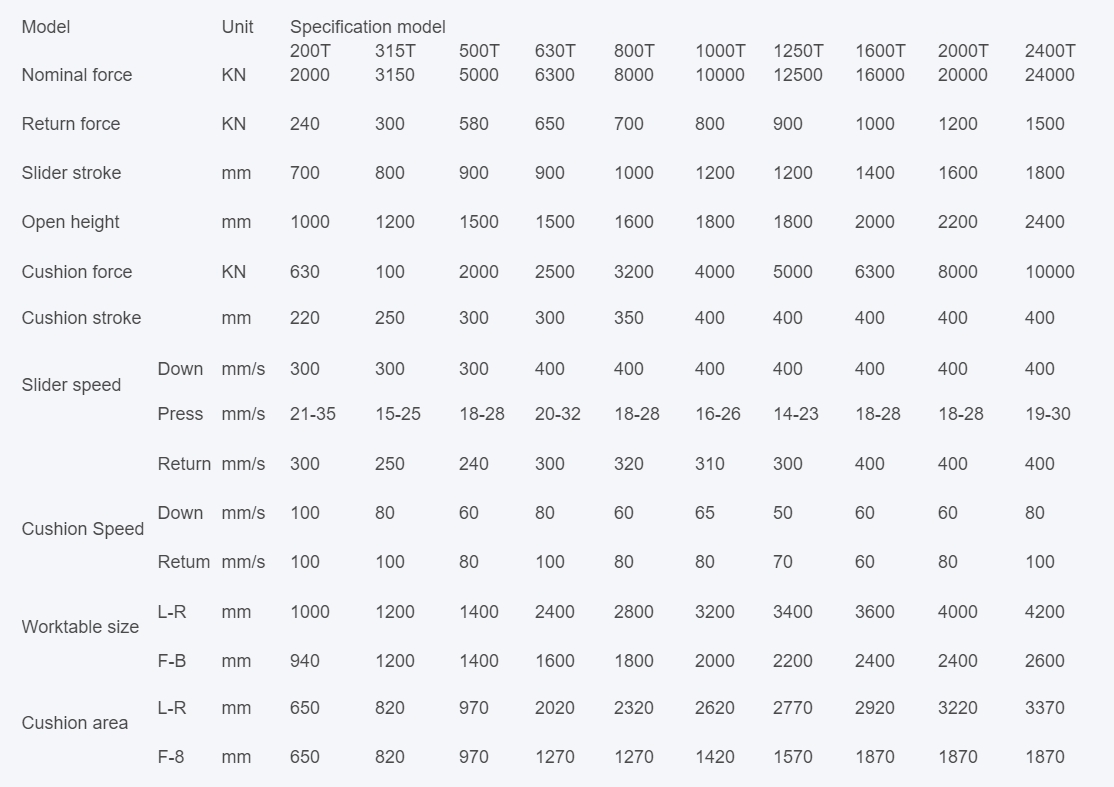

Model | Unit | Specification model | ||||||||||

200T | 315T | 500T | 630T | 800T | 1000T | 1250T | 1600T | 2000T | 2400T | |||

Nominal force | KN | 2000 | 3150 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 | 20000 | 24000 | |

Return force | KN | 240 | 300 | 580 | 650 | 700 | 800 | 900 | 1000 | 1200 | 1500 | |

Slider stroke | mm | 700 | 800 | 900 | 900 | 1000 | 1200 | 1200 | 1400 | 1600 | 1800 | |

Open height | mm | 1000 | 1200 | 1500 | 1500 | 1600 | 1800 | 1800 | 2000 | 2200 | 2400 | |

Cushion force | KN | 630 | 100 | 2000 | 2500 | 3200 | 4000 | 5000 | 6300 | 8000 | 10000 | |

Cushion stroke | mm | 220 | 250 | 300 | 300 | 350 | 400 | 400 | 400 | 400 | 400 | |

Slider speed | Down | mm/s | 300 | 300 | 300 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

Press | mm/s | 21-35 | 15-25 | 18-28 | 20-32 | 18-28 | 16-26 | 14-23 | 18-28 | 18-28 | 19-30 | |

Return | mm/s | 300 | 250 | 240 | 300 | 320 | 310 | 300 | 400 | 400 | 400 | |

Cushion Speed | Down | mm/s | 100 | 80 | 60 | 80 | 60 | 65 | 50 | 60 | 60 | 80 |

Retum | mm/s | 100 | 100 | 80 | 100 | 80 | 80 | 70 | 60 | 80 | 100 | |

Worktable size | L-R | mm | 1000 | 1200 | 1400 | 2400 | 2800 | 3200 | 3400 | 3600 | 4000 | 4200 |

F-B | mm | 940 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | 2400 | 2600 | |

Cushion area | L-R | mm | 650 | 820 | 970 | 2020 | 2320 | 2620 | 2770 | 2920 | 3220 | 3370 |

F-8 | mm | 650 | 820 | 970 | 1270 | 1270 | 1420 | 1570 | 1870 | 1870 | 1870 | |

Worktable eject pin layout | Layout | mm | 150×150 | 150×150 | 150×150 | 150X150 | 150×150 | 150×150 | 150×150 | 150×150 | 150X150 | 150X150 |

Number of rows | piece | 5*5 | 6°6 | 7*7 | 13*8 | 15*8 | 17*9 | 18*10 | 19’12 | 21*12 | 22*12 | |

Hole dia | mm | φ30 | φ40 | φ40 | φ40 | φ50 | φ50 | φ50 | φ50 | φ50 | φ50 | |

Motor power | KW | 16 | 20 | 40 | 50 | 66 | 75 | 95 | 130 | 200 | 230 | |

The optional robot automation system can be used to automate the production line.

The equipment is equipped with safety devices, a hydraulic double support insurance circuit, and a photoelectric protection system.

The hydraulic system adopts large-flow cartridge valve integration and is combined with a servo control system.

The fuselage adopts a pretensioned frame structure, and each structural member is welded with Q355B steel.