Mainly used for forming longitudinal beams of various passenger car and truck chassis, with tonnage ranging from 2500-6300 tons, and pressing longitudinal beams up to 12.5 meters.

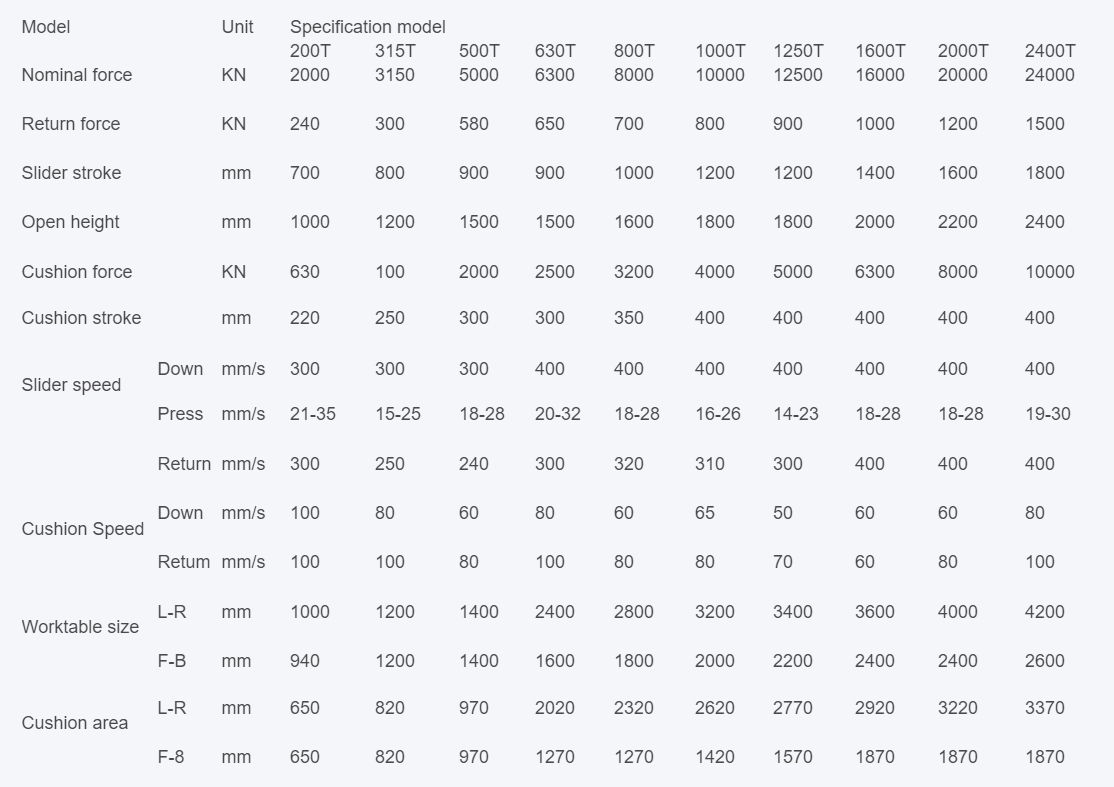

Model Aunit Specification model 200T 315T 500T 630T 800T 1000T 1250T 1600T 2000T 2400T Nominal force KN 2000 3150 5000 6300 8000 10000 12500 16000 20000 24000 Return force KN 240 300 580 650 700 800 900 1000 1200 1500 Slider stroke mm 700 800 900 900 1000 1200 1200 1400 1600 1800 Open height mm 1000 1200 1500 1500 1600 1800 1800 2000 2200 2400 Cushion force KN 630 100 2000 2500 3200 4000 5000 6300 8000 10000 Cushion stroke mm 220 250 300 300 350 400 400 400 400 400 Slider speed Down mm/s 300 300 300 400 400 400 400 400 400 400 Press mm/s 21-35 15-25 18-28 20-32 18-28 16-26 14-23 18-28 18-28 19-30 Return mm/s 300 250 240 300 320 310 300 400 400 400 Cushion Speed Down mm/s 100 80 60 80 60 65 50 60 60 80 Retum mm/s 100 100 80 100 80 80 70 60 80 100 Worktable size L-R mm 1000 1200 1400 2400 2800 3200 3400 3600 4000 4200 F-B mm 940 1200 1400 1600 1800 2000 2200 2400 2400 2600 Cushion area L-R mm 650 820 970 2020 2320 2620 2770 2920 3220 3370 F-8 mm 650 820 970 1270 1270 1420 1570 1870 1870 1870 Worktable eject pin layout Layout mm 150×150 150×150 150×150 150X150 150×150 150×150 150×150 150×150 150X150 150X150 Number of rows piece 5*5 6°6 7*7 13*8 15*8 17*9 18*10 19’12 21*12 22*12 Hole dia mm φ30 φ40 φ40 φ40 φ50 φ50 φ50 φ50 φ50 φ50 Motor power KW 16 20 40 50 66 75 95 130 200 230

The optional robot automation system can be used to automate the production line.

The equipment is equipped with safety devices, a hydraulic double support insurance circuit, and a photoelectric protection system.

The hydraulic system adopts large-flow cartridge valve integration and is combined with a servo control system.

The fuselage adopts a pretensioned frame structure, and the structural parts are welded from Q355B steel.