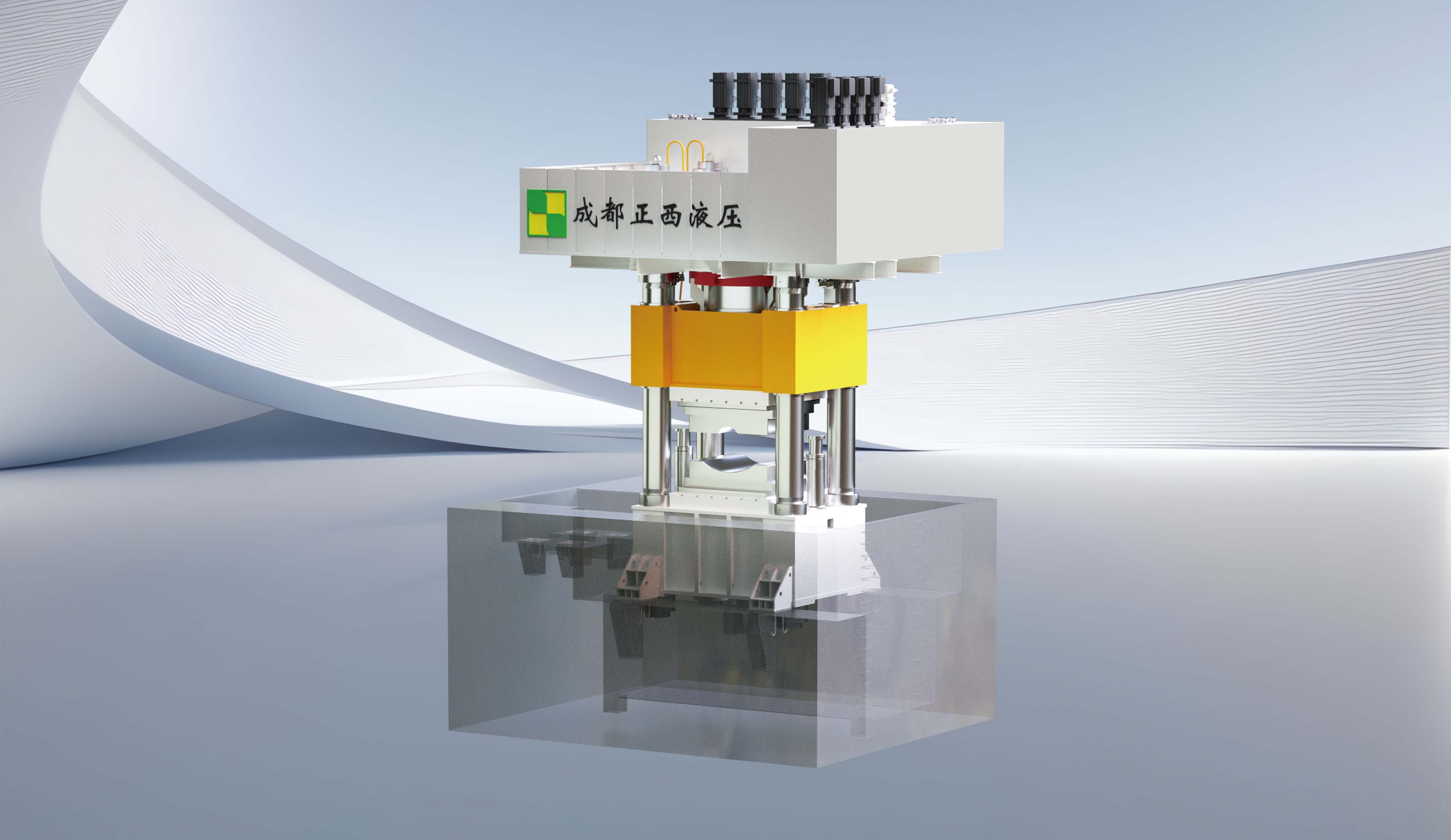

It is suitable for the forming process of various die forgings, aluminum alloys, titanium alloys, and other products.

The die-forging hydraulic press is suitable for automobiles, aerospace, shipbuilding, transportation, oil pipe fittings, and other industries.

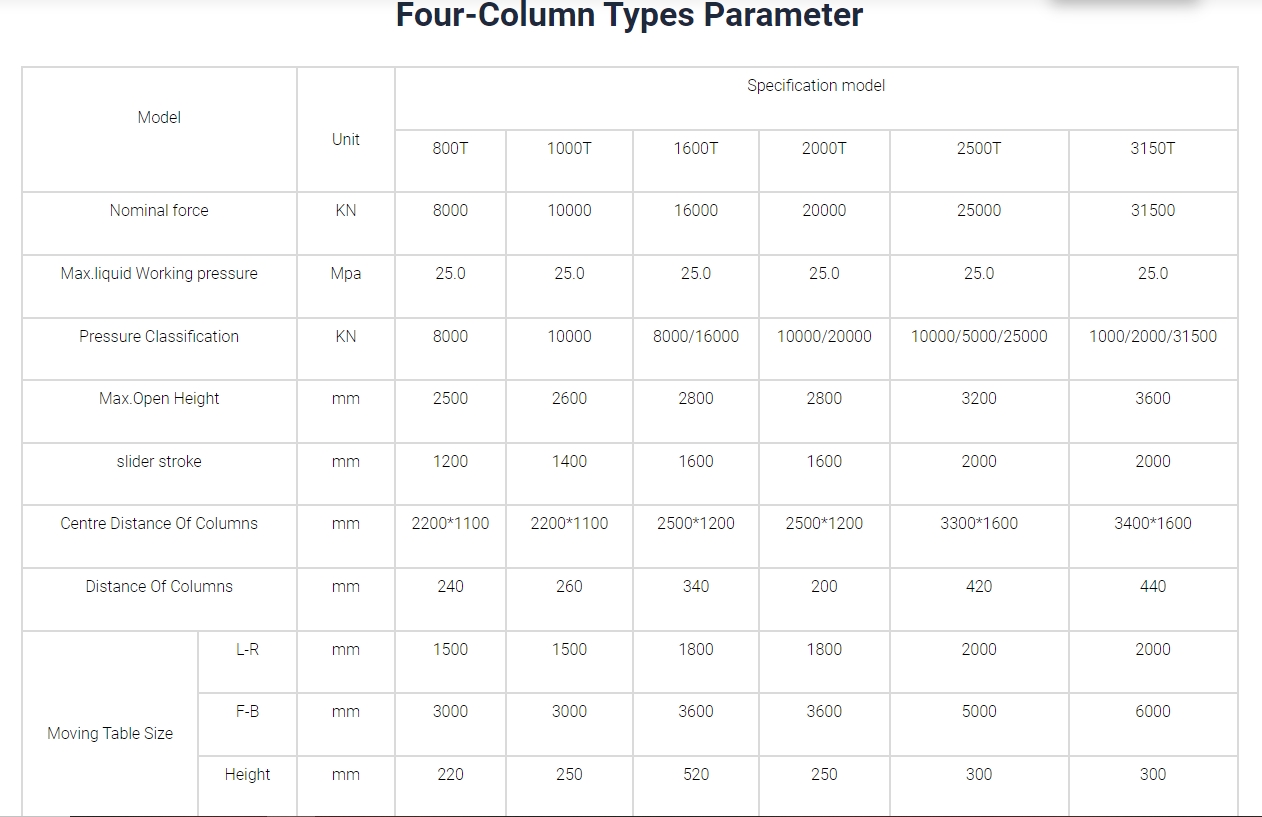

Model модель |

Unit

| Specification model | ||||||

800T | 1000T | 1600T | 2000T | 2500T | 3150T | |||

Nominal force | KN | 8000 | 10000 | 16000 | 20000 | 25000 | 31500 | |

Max.liquid Working pressure | Mpa | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | |

Pressure Classification | KN | 8000 | 10000 | 8000/16000 | 10000/20000 | 10000/5000/25000 | 1000/2000/31500 | |

Max.Open Height | mm | 2500 | 2600 | 2800 | 2800 | 3200 | 3600 | |

slider stroke | mm | 1200 | 1400 | 1600 | 1600 | 2000 | 2000 | |

Centre Distance Of Columns | mm | 2200*1100 | 2200*1100 | 2500*1200 | 2500*1200 | 3300*1600 | 3400*1600 | |

Distance Of Columns | mm | 240 | 260 | 340 | 200 | 420 | 440 | |

Moving Table Size Размер | L-R | mm | 1500 | 1500 | 1800 | 1800 | 2000 | 2000 |

F-B | mm | 3000 | 3000 | 3600 | 3600 | 5000 | 6000 | |

Height | mm | 220 | 250 | 520 | 250 | 300 | 300 | |

Moving Table Procedural Place | mm | 3 | 3 | 3 | 3 | 3 | 3 | |

Foring Eccentricity | mm | 100*60 | 100*60 | 140*70 | 140*70 | 150*100 | 200*120 | |

Slider speed | Down | mm/s | 400 | 400 | 400 | 400 | 400 | 400 |

Pressing | mm/s | 60 | 60 | 120/60 | 120/60 | 140/100/60 | 140/100/60 | |

Return | mm/s | 250-400 | 250-400 | 250-400 | 250-400 | 250-400 | 250-400 | |

Moving table speed | mm/s | 200 | 250 | 200 | 200 | 200 | 200 | |

Times of quick-forging | once/min | 50-60 | 50-60 | 50-60 | 50-60 | 50-60 | 50-60 | |

Main motor power

| KW | 440 | 380 | 850 | 1000 | 1350 | 1650 | |

Ultra-low speed isothermal forging function, closed-loop control, and displacement control can reach 0.005mm/s.

The pressure can be adjusted steplessly, and the control curve can achieve constant strain and variable strain.

It is equipped with a built-in sensor in the ejection cylinder to precisely control the feeding and ejection stroke.

The fuselage structural parts are welded with Q355B steel plates and are completely annealed after welding.