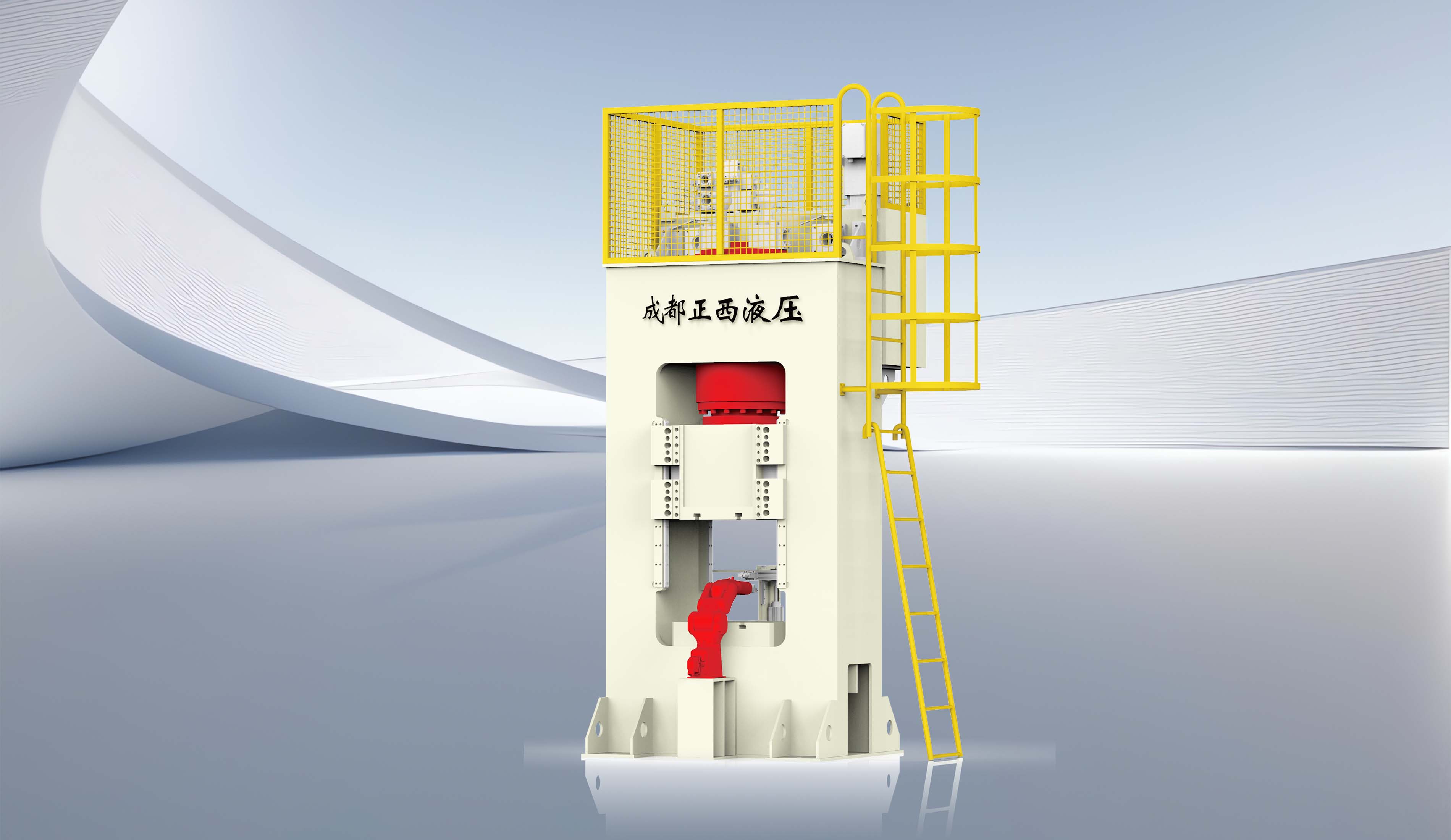

It is suitable for the forming process of various die forgings, aluminum alloys, and other products.

The metal extrusion molding hydraulic press is suitable for automobile, aerospace, shipbuilding, transportation, oil pipe fittings, and other industries.

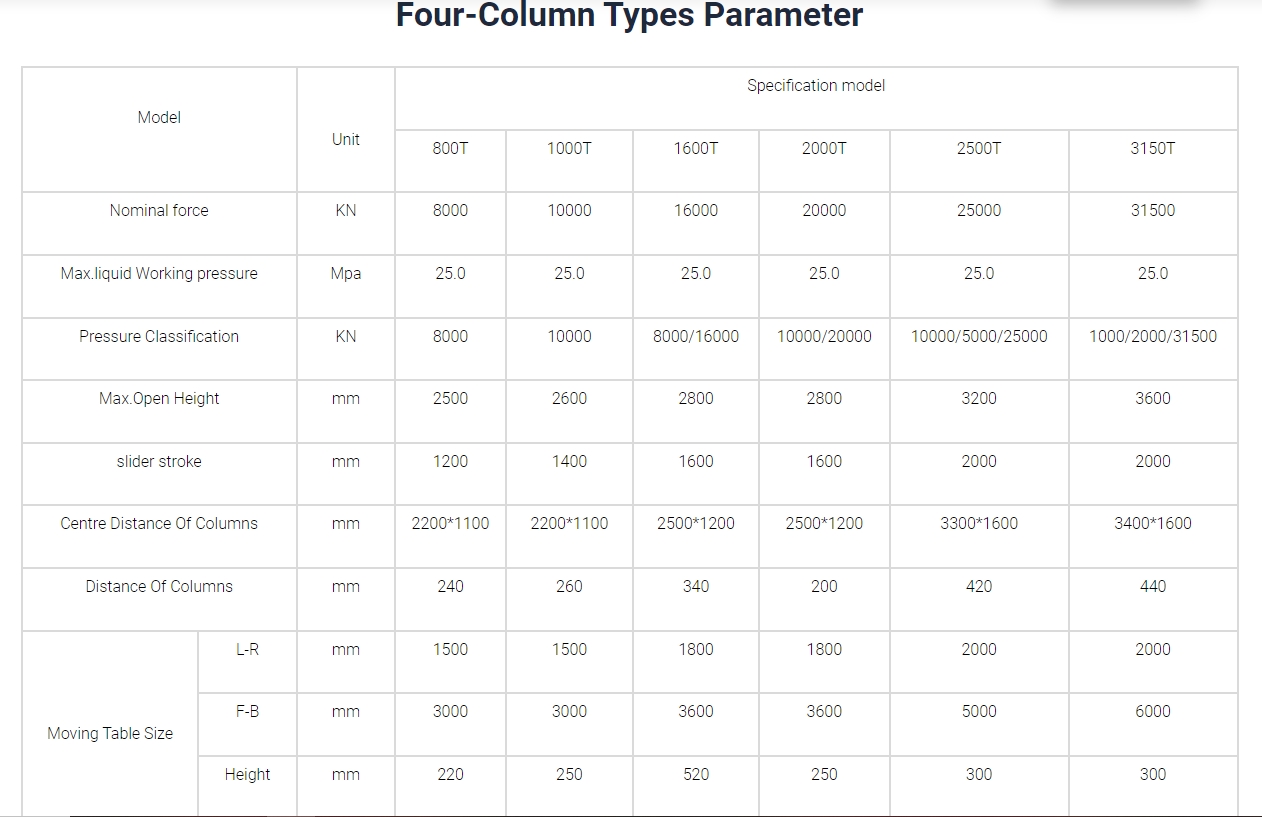

Model модель Unit Specification model 800T 1000T 1600T 2000T 2500T 3150T Nominal force KN 8000 10000 16000 20000 25000 31500 Max.liquid Working pressure Mpa 25.0 25.0 25.0 25.0 25.0 25.0 Pressure Classification KN 8000 10000 8000/16000 10000/20000 10000/5000/25000 1000/2000/31500 Max.Open Height mm 2500 2600 2800 2800 3200 3600 slider stroke mm 1200 1400 1600 1600 2000 2000 Centre Distance Of Columns mm 2200*1100 2200*1100 2500*1200 2500*1200 3300*1600 3400*1600 Distance Of Columns mm 240 260 340 200 420 440 Moving Table Size Размер L-R mm 1500 1500 1800 1800 2000 2000 F-B mm 3000 3000 3600 3600 5000 6000 Height mm 220 250 520 250 300 300 Moving Table Procedural Place mm 3 3 3 3 3 3 Foring Eccentricity mm 100*60 100*60 140*70 140*70 150*100 200*120 Slider speed Down mm/s 400 400 400 400 400 400 Pressing mm/s 60 60 120/60 120/60 140/100/60 140/100/60 Return mm/s 250-400 250-400 250-400 250-400 250-400 250-400 Moving table speed mm/s 200 250 200 200 200 200 Times of quick-forging once/min 50-60 50-60 50-60 50-60 50-60 50-60 Main motor power KW 440 380 850 1000 1350 1650

The hydraulic system is controlled by a cartridge valve, with small flow resistance and easy maintenance.

Due to the concentrated force on the machine, the slider and worktable adopt a reinforced design.