The molding process of automotive interior parts mainly includes injection molding, blow molding, extrusion molding, press molding, thermoforming, etc.

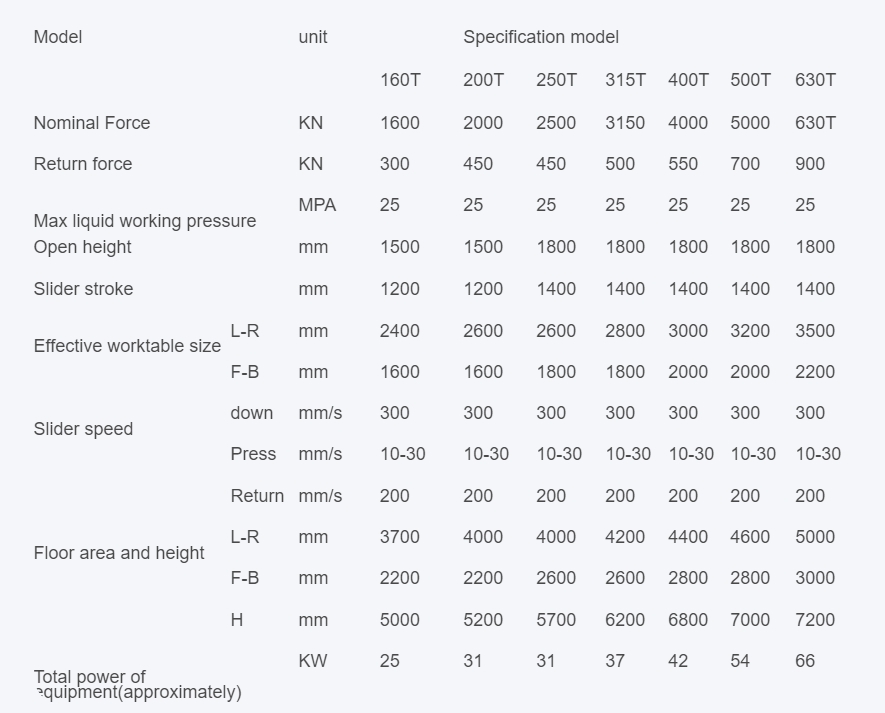

Model | unit | Specification model | |||||||

160T | 200T | 250T | 315T | 400T | 500T | 630T | |||

Nominal Force | KN | 1600 | 2000 | 2500 | 3150 | 4000 | 5000 | 630T | |

Return force | KN | 300 | 450 | 450 | 500 | 550 | 700 | 900 | |

Max liquid working pressure | MPA | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

Open height | mm | 1500 | 1500 | 1800 | 1800 | 1800 | 1800 | 1800 | |

Slider stroke | mm | 1200 | 1200 | 1400 | 1400 | 1400 | 1400 | 1400 | |

Effective worktable size | L-R | mm | 2400 | 2600 | 2600 | 2800 | 3000 | 3200 | 3500 |

F-B | mm | 1600 | 1600 | 1800 | 1800 | 2000 | 2000 | 2200 | |

Slider speed | down | mm/s | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

Press | mm/s | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | |

Return | mm/s | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

Floor area and height | L-R | mm | 3700 | 4000 | 4000 | 4200 | 4400 | 4600 | 5000 |

F-B | mm | 2200 | 2200 | 2600 | 2600 | 2800 | 2800 | 3000 | |

H | mm | 5000 | 5200 | 5700 | 6200 | 6800 | 7000 | 7200 | |

Total power of equipment(approximately) | KW | 25 | 31 | 31 | 37 | 42 | 54 | 66 | |

Compared with manual production, the molding process can greatly improve production efficiency and reduce production costs.

The molding process is used to ensure the accuracy and dimensional consistency of automotive interior parts, thereby improving product quality.

Automotive interior parts of various shapes and structures can be produced, with better plasticity and design freedom.