Many automotive interior parts require the use of composite processes for processing and production, such as car seats, door panels, instrument panels, center consoles, etc.

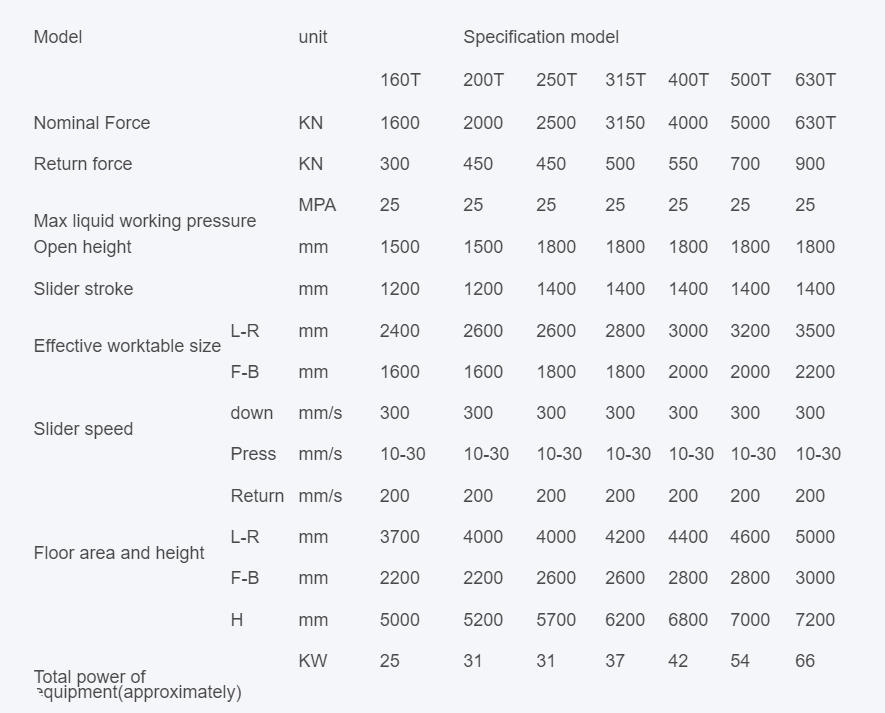

Model unit Specification model 160T 200T 250T 315T 400T 500T 630T Nominal Force KN 1600 2000 2500 3150 4000 5000 630T Return force KN 300 450 450 500 550 700 900 Max liquid working pressure MPA 25 25 25 25 25 25 25 Open height mm 1500 1500 1800 1800 1800 1800 1800 Slider stroke mm 1200 1200 1400 1400 1400 1400 1400 Effective worktable size L-R mm 2400 2600 2600 2800 3000 3200 3500 F-B mm 1600 1600 1800 1800 2000 2000 2200 Slider speed down mm/s 300 300 300 300 300 300 300 Press mm/s 10-30 10-30 10-30 10-30 10-30 10-30 10-30 Return mm/s 200 200 200 200 200 200 200 Floor area and height L-R mm 3700 4000 4000 4200 4400 4600 5000 F-B mm 2200 2200 2600 2600 2800 2800 3000 H mm 5000 5200 5700 6200 6800 7000 7200 Total power of equipment(approximately) KW 25 31 31 37 42 54 66

It refers to taking advantage of the characteristics of different materials and combining them through processes such as bonding and hot pressing.

With higher strength and stiffness, it can improve the durability and impact resistance of automotive interior parts.

Composite materials are generally more durable than traditional materials and can extend the life of automotive interior components.