Many automotive interior parts require punching/cutting processes for processing and production, such as car seats, door panels, instrument panels, center consoles, etc.

In addition, automotive interior parts punching/cutting technology is gradually being used in other fields, such as furniture, building materials, and other fields.

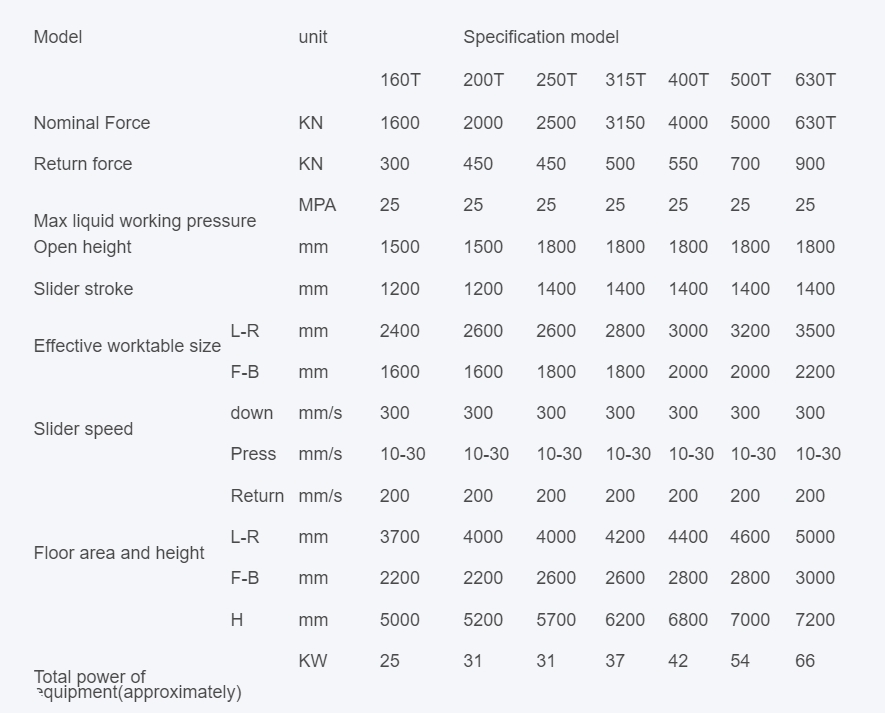

Model unit Specification model 160T 200T 250T 315T 400T 500T 630T Nominal Force KN 1600 2000 2500 3150 4000 5000 630T Return force KN 300 450 450 500 550 700 900 Max liquid working pressure MPA 25 25 25 25 25 25 25 Open height mm 1500 1500 1800 1800 1800 1800 1800 Slider stroke mm 1200 1200 1400 1400 1400 1400 1400 Effective worktable size L-R mm 2400 2600 2600 2800 3000 3200 3500 F-B mm 1600 1600 1800 1800 2000 2000 2200 Slider speed down mm/s 300 300 300 300 300 300 300 Press mm/s 10-30 10-30 10-30 10-30 10-30 10-30 10-30 Return mm/s 200 200 200 200 200 200 200 Floor area and height L-R mm 3700 4000 4000 4200 4400 4600 5000 F-B mm 2200 2200 2600 2600 2800 2800 3000 H mm 5000 5200 5700 6200 6800 7000 7200 Total power of equipment(approximately) KW 25 31 31 37 42 54 66

Punching/cutting refers to the processing and production of automotive interior parts through stamping or cutting and other processes.

Automotive interior parts can be processed quickly through certain molds and machinery to improve production efficiency.

Through mass production and reuse of molds, production costs can be reduced and economic benefits improved.