We have the experience and ability to develop and construct large-scale rolling furnace sheet hot-forming stamping lines, box-type furnace sheet hot-forming stamping lines, and production lines.

We can develop and customize high-temperature thermoforming stamping production lines, hot stamping loading and unloading manipulators, and single-machine multi-station stamping line robots according to customer needs.

1. Body parts: side panels, roof, door inner and outer panels (four pieces in one mold), small and medium-sized automobile parts - swing arm, main body, rear panel, left and right front longitudinal beams, reinforcing plates, roof reinforcing beams, door sills, and relatively Chain reinforcement plates, etc.

2. Home appliances: range hood smoke collection chamber, rice cooker liner, microwave oven front door, side panels, water heater end cover and dishwasher smoke guide plate, TV back panel, refrigerator door shell, washing machine front cover, side panels, motor housings, and air conditioner housings, etc.

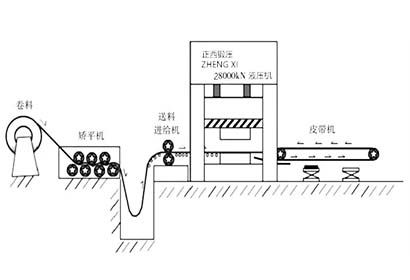

3. It can be customized from roll materials or stacked plates to molded parts. The molding speed is fast and safe. The fastest can be completed at 5 sheets/min.

4. The automatic production line has an automatic centering function, with strong product consistency and high precision.

1. Type: joint robot, stepping manipulator, rapid heating insulation line, etc.

2. Net load: 0.1~3000Kg

3. Positioning accuracy: ±0.03mm

4. Transposition rhythm: 1~12 beats/min

5. Temperature range: 0~1250℃

1. The hot stamping loading and unloading robot and production line are composed of a stamping machine loading manipulator, a stamping machine unloading manipulator, a heating furnace loading manipulator, a heating furnace unloading manipulator, an alignment platform, a control system, etc. The manipulator adopts two-speed and four-speed telescopic manipulator arms, which run at high speed. The hot stamping robot completes a series of functions of steel plates from depalletizing to unloading, press feeding, stamping machine loading, and stamping machine unloading. In response to the requirements of large load and rapid operation of the robot within a large stroke range, Zhongtuo Robot has developed a box-type furnace-enhanced hot stamping production line.

2. Each axis operates independently, there is no multi-axis cumulative error, the operation speed is fast, the service life is long, the repeat positioning accuracy is high, the clamping positioning is more accurate than the multi-joint robot, and it is more cost-effective than the six-joint robot, making it more suitable for large and small factories. Automated supporting processing.

3. Can be easily matched with various detection sensors (in-line clamp head, clamp head side-mounted sensor, side cover sensor, contact rod sensor).