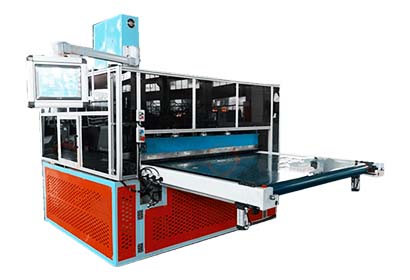

1. The equipment is mainly used to automatically feed the cut sheets into the press, and effectively lay the sheets on the mold, eliminating the need for manual laying of materials into the press.

2. Can shorten the curing time in the mold by up to 1/3.

3. Automatic laying, adaptable to the laying of different materials, improves the safety performance of molding.

4. One-time laying of materials solves the problem of solidification of front materials caused by slow manual laying of materials.

5. Installed in the front direction of the press feeding, and connected with the equipment to achieve automation. The whole machine can be removed when not in use.

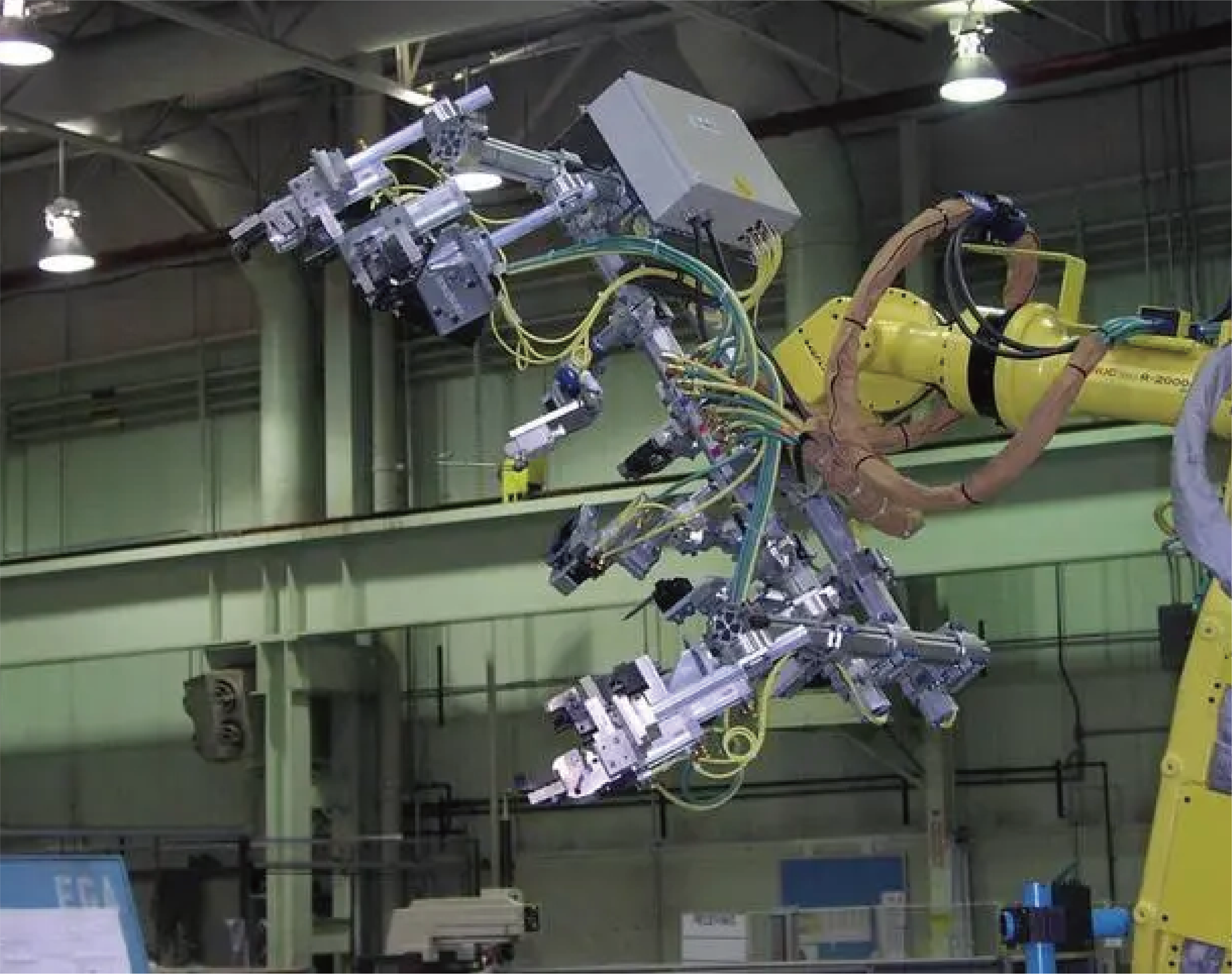

1. The automated front-end and rear-end of customized composite molding, the most important pick-up device, is independently designed and manufactured by Zhengxi.

2. The customization range of end picks covers materials such as sheets, pellets, prepregs, gauze, and braided materials.

3. Two kinds of end picks, hot grip and cold grip at 20~300℃, can be customized for quick grabbing and quick release.

4. Applicable workpieces: length 50~3000mm, width 50~2000mm, weight ≤50KG.

5. Can be easily matched with various detection sensors (in-line clamp head, clamp head side-mounted sensor, side cover sensor, contact rod sensor).

6. Multiple installation methods (axial, lateral, universal) for easy debugging.

7. Self-locking design, the clamping state can be maintained even if the air is cut off.

1. Automatic feeding machine

2. Automatic preheating (warming) machine

3. Loading and unloading robot

4. Intelligent temperature control system/vacuum system

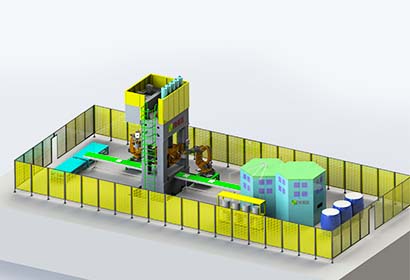

1. Automatic film tearing and slicing machine

2. Compensation weighing machine

3. Stock preparation line/visual alignment

4. Feeder/composite conveyor belt

5. Preheating machine (reducing mold pressure time)

6. Loading and unloading robot

7. Intelligent temperature control system/vacuum system

1. Automatic dicing machine

2. Compensation weighing machine

3. Stock preparation line/visual alignment

4. Preheating machine (reducing mold pressure time)

5. Loading and unloading robot

6. Intelligent temperature control system/vacuum system

1. Automatic film tearing and slicing machine

2. Compensation weighing machine

3. Stock preparation line/visual alignment

4. Feeder/composite conveyor belt

5. Preheating machine (reducing mold pressure time)

6. Loading and unloading robot

7. Intelligent temperature control system/vacuum system