Zhengxi Cloud Platform opens up the core capabilities of industrial data full life cycle processing in a "cloud-based manner" to build data basic open capabilities and realize multiple levels of open capabilities such as data management, basic analysis algorithms, data presentation, open interfaces, and development environments.

Zhengxi Cloud Platform will be able to link massive industrial equipment, manage high-value industrial assets, create unique solutions based on the business characteristics of various fields in specific industries, integrate business processes or management features, and assist enterprises in building their own industrial big data applications.

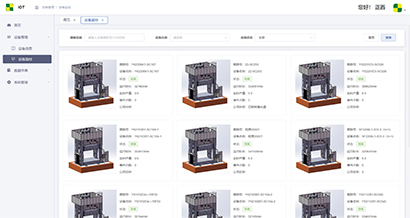

Zhengxi Cloud Software System is committed to scientific equipment management, taking the whole life cycle as the main line and preventive maintenance as the center. It also takes into account the management of equipment files and equipment map boards. It also introduces IoT technology to realize real-time monitoring of equipment status and real-time fault alarms to help enterprises achieve standardized, scientific, and intelligent management of equipment, reduce equipment failure rates, maintain equipment stability, and achieve an overall improvement in enterprise asset efficiency.

1. Fault reporting: Users can report faults.

2. Work order dispatch, supports manual dispatch, and manage maintenance work orders such as dispatch, reception, cancellation, and work order reminders.

3. Support maintenance process records, upload pictures, maintenance hours, spare parts consumption, maintenance amount, etc., and display maintenance progress in real-time.

4. The system automatically displays the repair request and maintenance process in a timeline.

1. Supports panel control of indicators, which is clickable and traceable. The indicator positions can be arranged according to customer preferences.

2. Single indicator data can be queried at any time and the data location can be located.

3. Support data aggregation query, with different aggregation methods for different indicators, such as output accumulation and energy consumption converted from current.

4. Real-time changes in data are synchronized, one-to-one with production equipment.

1. Reflect on the current operation status of the equipment.

2. Today’s equipment production curve, electricity consumption, and production for the month.

3. Equipment operating status in various states, equipment utilization curve, yesterday's output, and yesterday's utilization change trend.

1. Support viewing device alarm statistics and device alarm details.

2. Combine with customized alarm information to set up richer and freer alarm management.

3. Through two dimensions, the number of alarms and the alarm type, and the duration.

1. View device data on the map, locate the device, and view device details.

2. Combine charts and lists to meet customer usage habits.

3. Support equipment maintenance information and customized alarm information for equipment.

4. Support device cloud monitoring.