You can find news and information about the Zhengxi Group

So that you can be the first to know the latest news

After centralized large-scale power stations and agricultural photovoltaic power plants, industrial and commercial photovoltaic upgrades are about to become a new growth explosion point in the photovoltaic market.

Boron fibers are inorganic fibers formed by depositing boron on metal wires. Hydrogen and boron trichloride are usually reacted on a red-hot tungsten filament to replace the amorphous boron and deposit on the surface of the tungsten filament, which is a brittle material. Boron fibers are generally produced by chemical vapor deposition.

Spring rain and green grass take root. April has passed. The people of Zhengxi, across the mountains, rivers, lakes and seas, gathered together to participate in the grand event.

Every exhibition brings together elites from all walks of life.

Each exhibitor showcased the best products and services.

Let every exhibitor feel the vitality of the industry.

On January 28 (the seventh day of the first lunar month), after the groundbreaking ceremony just ended yesterday, Zhengxi immediately welcomed a group of friends from afar, a delegation of Belarusian enterprises and representatives of the Belarusian Embassy in China to visit the company.

The epidemic is still repeating

Since the beginning of the epidemic in 2020, the employment of graduates has become a key problem in the graduation season of various universities.

Chengdu Zhengxi Group has gone through 13 years since 2009.

In the new five-year plan of Zhengxi Group, Chairman Zeng Huan emphasized the importance of talent reserve and talent introduction to Zhengxi.

Chairman Zeng proposed in the plan that talent is an important reference point to help the development of enterprises, and in the next five years, Zhengxi is in the process of continuous development

A large number of talents are needed to support development.

It has always been the purpose of Zhengxi Group to cultivate talents, improve their abilities, and continuously strengthen their ability to deal with and solve problems.

It is also the obligation of Genxi Group to provide stable jobs and a good learning environment for college graduates.

The pandemic is raging

But Zhengxi is full of warmth

ZHENGXI DATONG Association

Closed-loop management at the same time

It also makes every Zhengxi person feel warm

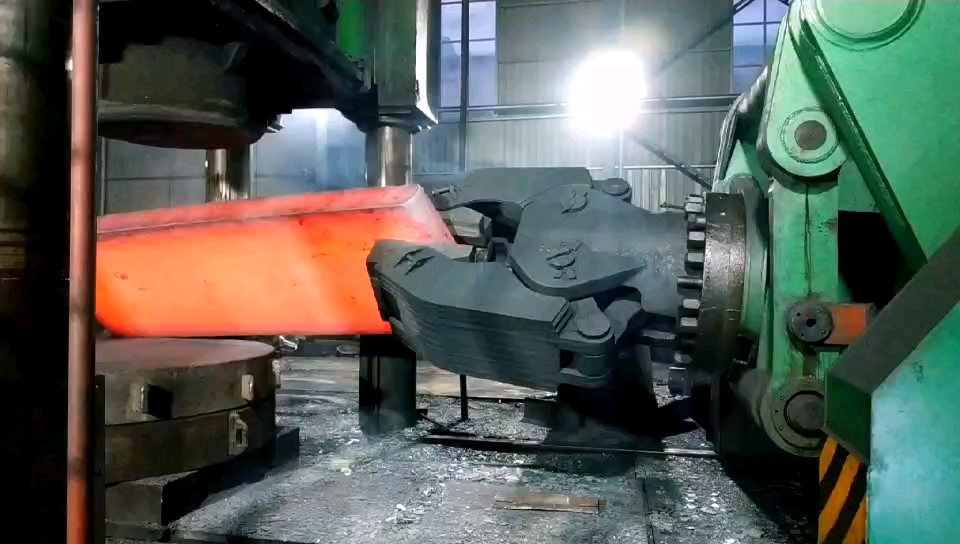

Forged flange is a common part in industrial production, and its quality is directly related to production safety and product quality. So, how to test the quality of forged flanges?

Titanium alloys have many advantages, such as high strength, good corrosion resistance, non-magnetism, and good welding properties, in addition to several advantages such as superconductivity, hydrogen storage, and memory. Titanium alloys are widely used in aerospace, military industry, marine development, petrochemical and other frontier fields.

Titanium alloy forgings are one of the various titanium alloy products, which are mainly used in occasions that require high strength, high toughness and high reliability, such as steam turbine compressor discs and medical artificial bone. Therefore, forged parts are required not only to be dimensionally accurate, but also to have excellent performance and stability.

Isothermal forging is a high-temperature forging process, which can improve the microstructure and properties of forgings, and improve the mechanical properties and heat resistance of forgings. So, what kind of forgings need to be isothermal forged?

Generally speaking, if the hydraulic press fails, it is the first time to contact the manufacturer to solve it. But sometimes the machine may just have a little bit of a fault, instead of waiting for the maintenance personnel to come to the door, it is better to try to solve it yourself!

The article I share with you today is to teach you to solve the problems and solutions that may be encountered in the daily use of the four-column hydraulic press!

Follow us, more hydraulic press knowledge is waiting for you to come and see~

The most common cause of overheating of hydraulic presses is improper adjustment. This is the first thing we find in a device that doesn't usually overheat. The pump compensator is the most common unbalance component, and the compensator must be located under the equipment safety valve. But whatever the reason, the system works better at higher pressures